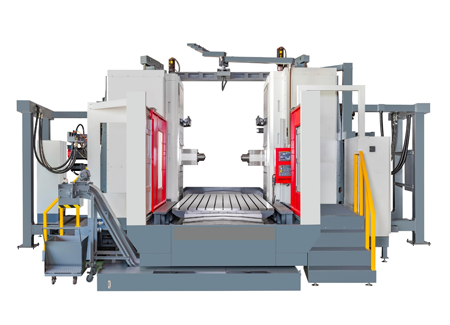

Horizontal milling machine UMm-4216D

time:2021/12/21 10:24:44

Views:

Service hotline15652234768

1. Machine characteristics

1. Base (X axis)

The base is welded and formed by high-tensile steel plates according to customer requirements and tempered to achieve the stability of the machine. The X-axis adopts SCHNEEBERGER or THK roller linear rails, which can meet the requirements of high load and high rigidity. The X-axis travel is more than five meters. , Are equipped with optical scales to ensure processing accuracy. Both sides of the base are equipped with spiral chip conveyors, which can discharge chips to the tail end of the chain chip remover, effectively maintaining the cleanliness of the environment.

Two widened column bases are locked on each side of the X-axis base, and the contact area between the base and the ground is increased by more than 150%, making the column more stable and increasing the overall machine rigidity.

2. Column (Y1, Y2 axis)

The Y1 Y2 axis column seat stands on the widened base on both sides of the X axis. It is supported by two roller type M55 linear rails at the front. Each rail has three sliding blocks, and there are two M35 roller type linear rails behind the column. , Each rail is supported by two sliding blocks, which can effectively prevent the sag when the square ram is extended. The front and rear four branch rails form a four-point support, and when the entire head moves up and down, it looks even more stable. The Y-axis is driven by a C3 precision ball screw with a diameter of 63MM, except that there is a counterweight on each side of the column, and it is locked on a two-line rail, so that the up and down movement is stable and smooth.

3. Head (Z1, Z2 axis)

Z1 Z2 axis is a 420X420 (MM) square ram spindle head, equipped with 4000RPM spindle.

Optional 6000rpm main shaft, main shaft and servo motor are connected through toothed belt and variable speed gear box, the highest gear ratio can reach 1:8.25, and the main shaft output torque can reach 1155/1364Nm, which can easily reach high for mold steel and steel components. High-efficiency cutting processing.

4. Workbench

Optional 4000X1400MM workbench, installed on the X-axis base, with two SCHNEEBERGER or THK roller-type linear rails, X-axis transmission is driven by 80MM C3 grade ball screw, the workbench structure adopts double-wall cage structure, with high load , Low friction resistance, suitable for various fine processing.

5. Lubrication

Automatic lubrication system, using closed-pole continuous lubricating machine, can ensure enough lubricating oil for each lubrication point; each sliding surface and ball screw are distributed according to the oil path, and the oil volume is controlled separately. The cycle lubrication time can be set according to needs, with Low oil control device. The cooling water tank uses a split design, so that the chips are easy to clean and the cooling water is easy to replace.

6. Chip removal

There are a set of cutting screws on the left and right sides of the base, which can transport the chips to the chain conveyor at the front end to keep the machine clean. The front chain chip conveyor can discharge the chips collected by the chip screw out of the machine. The water tank can be pulled out of the machine to facilitate the cleaning of the water tank. It can be equipped with an oil-water separator to avoid the quality change or bad smell of the cutting fluid.

7. Tool magazine

Optional (24, 32, 40) tool magazines, side back on the side of the column, and guided to the spindle end by a chain track to perform tool change, stable movement and extremely low failure rate.

LAST:none